1949

In 1949 Maurizio Rossi and Luigi Cristina founded the company Officina Meccanica Sestese in Arona (Northern Italy). In those difficult post-war years, the Company undertook the important task of producing equipment and accessories for the brick and tile industry.

1958

OMS’ production soon asserted itself on the market so much that after a few years it became necessary to change premises. So, in 1958 a new plant was inaugurated in Arona where it continued to produce technologically advanced kiln equipment.

1962

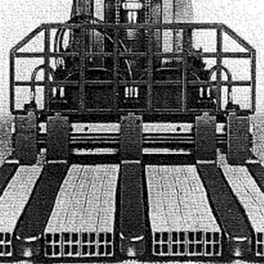

First International Patent: “ Artiglio Fork” for bricks. Sold in all five continents.

1976

New Headquarter in Paruzzaro

1980

First Strapping Head Model R10

1990

AT62 New thermoshrink hooding machine

1992

Strapping Head Model TR14

1999

OMS celebrates its 50th Anniversary

2000

First Thermoshrink hooding machine AT53

2004

Acquisition of OMSTRAP in - Sandigliano (Biella), for strap and consumables production

2006

New Stretch hooding machine model IS43

2010

ISM bundle strapper, for the paper and cardboard industry

2014

The new high yield IS46 stretch hooding machine

2018

Today, Officina Meccanica Sestese offers a complete range of end-of-the-line packaging machines and systems. Thanks to the great reliability of its machines, guaranteed by years of experience, and its production versatility, OMS Group can satisfy all market requirements from the simplest strapping machine to the most sophisticated packaging system.

2019

Officina Meccanica Sestese celebrates its 70th anniversary.

An important milestone in our History.

An important milestone in our History.

2022

New strapping head model VYBRO Plus

Maurizio Rossi

Luigi Cristina

Artiglio Fork

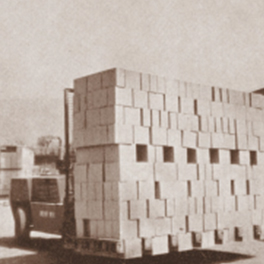

Fork lift & Artiglio Fork

Stabilimento di Paruzzaro

Headquarters in Paruzzaro

Strapping head TR14

Stretch Hooder IS43

Our "first" 70 years

Logo created for this event

OMS in the world

-

1000

Machines produced every year

-

450

People working synergically every day

-

22000

The area of Paruzzaro’s works

-

12

OMS worldwide branches

-

75

Years of worldwide presence in the field

Philosophy And objectives for the Future

-

Consolidation and extension of the worldwide sales and assistance network

-

Adoption of state-of-the-art machine design and manufacturing technologies

-

Adoption of new and more sophisticated machine management and diagnosis software which also allows for remote machine operation control and programming (through a modem)

-

Orientation towards the supply of complete "packaging solutions" to be integrated in production lines instead of single machines

-

Adaptation of machines to the most recent energy savings requirements

-

Possibility for the machines to properly work with materials with a low environmental impact