Palletless

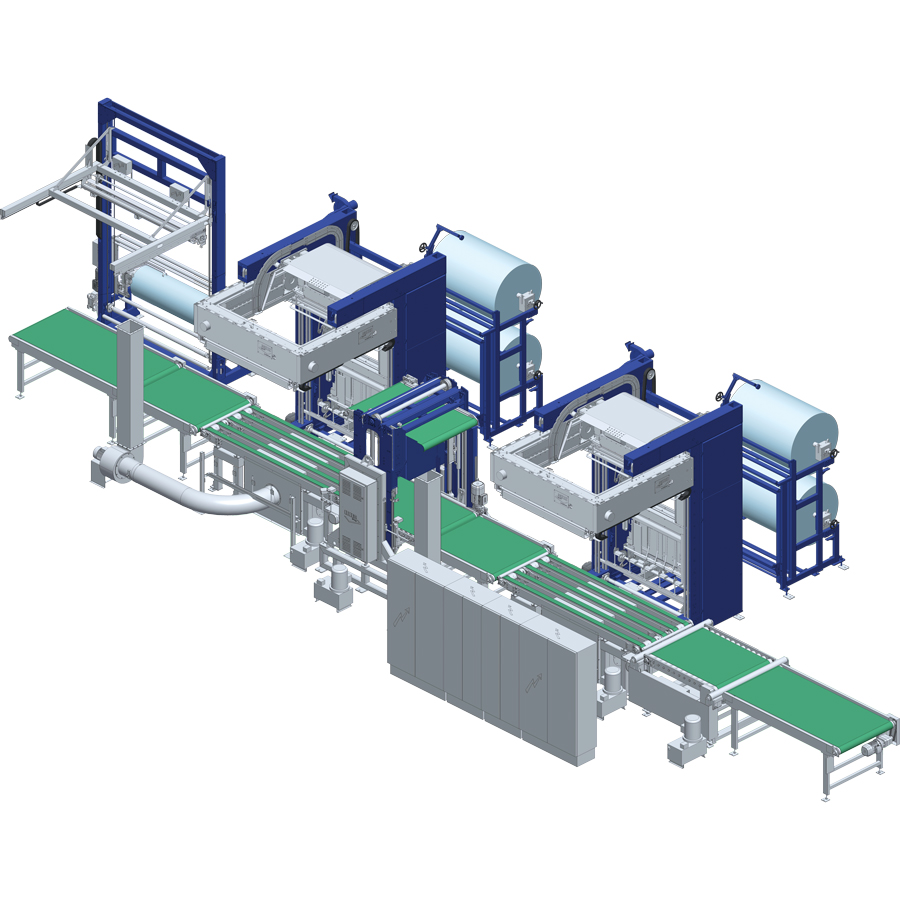

The PALLETLESS packaging technology is a modular line that can be easily adapted to the costumer’s manufacturing needs.

This packaging solution brings many benefits, first of all, a money saving due to the costs reduction for the purchase of pallets and their processing and in the secondly a space reduction due to smaller size of the load.

Another benefit comes from the packaging method, the film shrinking ensures the highest impermeability of the packs, making it possible to store them outdoors.

Our palletless line is usually made up by:

- TOP SHEET DISPENSER MTF10

Automatic film application system with top sheet dispenser to apply a sheet of thermoshrinking film on top of the pack. The sheet is taken from a coil installed on the machine and it is made to protrude from the pack as needed.

- COMBINED SHRINK HOODING AT53 click here for details

- (or IS43 on alternative request)

Hooding and hot air shrink system with four linear burners (OMS patent and validation n. DG2217 BL 0557 issued by the German Gas Institute), which guarantee a thermal balance to favour the use of a very low thickness and the ideal heat distribution. The hooding machine can work automatically even with different coils with equal or different dimensions and thicknesses.

- ROTATOR RT02

Automatic rotation system with which it is possible to turn the pack by 180° in order to obtain a perfectly sealed packaging. Pack compression is controlled by an oil-pressure unit.

Palletless lines with different production capacities are available:

TECHNICAL DATA

| Pack dimensions: | 1050mm x 1250mm x 1370mm |

| Max weight: | 2200 Kg |

| Film thickness: | 140 mk |

| Output: | 60 / 80 / 100 Pack /Hour |

Information request