News

ECOMONDO 2019 – Rimini

From the recovery of materials and energy to sustainable development. All sectors of the circular economy on a single platform.

The benchmark event in Europe for technological and industrial innovation. An international event with an innovative format that brings together all sectors of the circular economy on a single platform: from the recovery of materials and energy to sustainable development.

The event helps companies become world leaders in innovation, promoting the development of an innovative and sustainable entrepreneurial ecosystem.

ECOMONDO supports the companies to make contact with the most skilled national and international buyers and work all year with a targeted community with the leading experts in the circular economy.

The OMS group will participate for the first time presenting a strapping kit suitable to meet the needs of the waste sector. Don’t miss this appointment!

Between 5 and 8 Nov, 2019 our Sales staff, will be happy to welcome you at Hall A3 – booth 181

More details: https://www.en.ecomondo.com/

PRESS MASTER PLUS ON STAGE

HIGHEST PERFORMANCE meets LOWEST PRODUCTION COSTS

OMS Group was on stage at the FEFCO Technical Seminar in Geneva with their new Generation of an modular intelligent High Speed Pallet Strapping Press for an INDUSTRY 4.0 automation.

The Fully Automatic High Performance System PRESS MASTER PLUS are equipped with an,

- Intelligent Compression Speed

- Intelligent Compression Force

- Intelligent Compression Height

- Intelligent Ultra Sonic Sealing Head SONIC Plus

to optimize your Packing Result & Reducing your Costs.

We manage with our new “OMS Intelligent COMPRESSION Control”

of the load with the result that you will get the Highest Load Securement & optimized Load Height.

Our First 70th years

This year, OMS celebrate its 70th year of foundation with a series of events specifically thought of for this important moment.

OMS Group is a world leader for end-of-line packaging of palletized products for all market sectors. In addition to the Italian headquarter the Group consists in 11 subsidiaries based in Italy, Europe, North and South America, Asia and Oceania.

LIGNA 2019 – Hannover

LIGNA is the world’s leading trade fair for machinery, plant and tools for the woodworking and timber processing industry. The show will have a strong focus on the role of automation and digitization in combining the customer-centricity of product individualization with the economies of scale of large-series production. Apart from digitization, the main drivers of this boom for wood-industry technology suppliers are the worldwide megatrends of sustainable building and urbanization.

OMS Group is participating in this edition, presenting a packaging machine suitable for satisfying the multiple needs of the wood sector. You can’t miss this appointment!

Between 27 and 31 May, 2019 our Sales staff, will be happy to welcome you at Hall 26 – stand E08

More details: https://www.ligna.de/home

BAUMA 2019 – Munich

BAUMA is more than the world’s leading trade fair: it is the heartbeat of the industry. It sets the pace. Dynamizes the market. And drives business. With one paramount goal: to always already focus on the next challenge. Because it’s not just about the status quo, but about the future.

Because it’s not just about individual perspectives, but about the big picture: the construction, building material, mining machine industry, all related accessories in its full dimension.

OMS Group is participating in this edition, presenting a packaging line suitable for satisfying the multiple needs of the sector. You can’t miss this appointment!

Between 08 and 14 April, 2019 our Sales staff, will be happy to welcome you at Hall C1 – stand 238

More details: https://www.bauma.de/index-2.html

SONIC Plus – Ultra Sonic Sealing Technology

The SONIC Plus model strapping head, with its innovative Ultra Sonic Sealing Technology, represents the state-of-the-art in the field of strapping heads.

Thanks to its compact size and reduced weight, the new ultrasonic head is easy to move for maintenance and replacement. No waste of time during these operations.

LOGIMAT 2019 – STUTTGART

A top event for in-company material flow and computer-controlled processes from procurement to production and distribution…in the heart of Europe.

LogiMAT, the International Trade Fair for Intralogistics Solutions and Process Management, sets new standards as the biggest annual intralogistics exhibition in Europe. This is the leading international trade fair that provides a comprehensive market overview and competent knowledge-transfer.

OMS Group will participate for the first time in this important event, with an automated line solution, with a 4.0 perspective, interconnected and integrated with the factory’s IT and logistics system and intelligent production assistant robots in collaboration with SEW-EURODRIVE (www.sew-eurodrive.it), one of our most important partners and suppliers..

Between 19 and 21 February 2019, our Sales staff, will be happy to welcome you at Hall Nr.4 – booth A45

More details: https://www.logimat-messe.de/en

Pinguin Lutosa

Gordian Strapping LTD, our distributor in the U.K. has provided Pinguin Lutosa with a sistematic solution at their site of King’s Lynn.

Pinguin Lutosa, a leading frozen vegetable processor boasts some of the best automated packing facilities in Europe. The Kings Lynn site is a state of the art production and packing site with capacity to produce over 120,000 tonnes of product p.a. Gordian has integrated a AVR 900 automatic pallet ring wrapper into Pinguin’s packaging line.

The machine replaced an ageing rotary arm wrapper and is part of a programme of upgrades to the automated packaging facility at Kings Lynn. It was essential that the Ring Wrapper matched the footprint of the old machine and was compatible with the existing conveyor and safety systems.

It was also vital for the new machine to overcome the costly issue of loose film tails which can lead to rejection of pallets by automated warehousing systems. Rapid installation over a weekend was critical to ensure minimum disruption to the freezing of fresh vegetable produce.

Pinguin Lutosa has the AVR 900 Ring Wrappers in operation at their site in Belgium and had no hesitation in installing another machine in the UK.

Palletless systems

The core of the palletless system of OMS is the SEW-Eurodrive technology, a German multinational, one of the world leaders in industrial automation. Many of the components installed in the WHO machines are supplied by the company born in northern Germany more than eighty-five years ago.

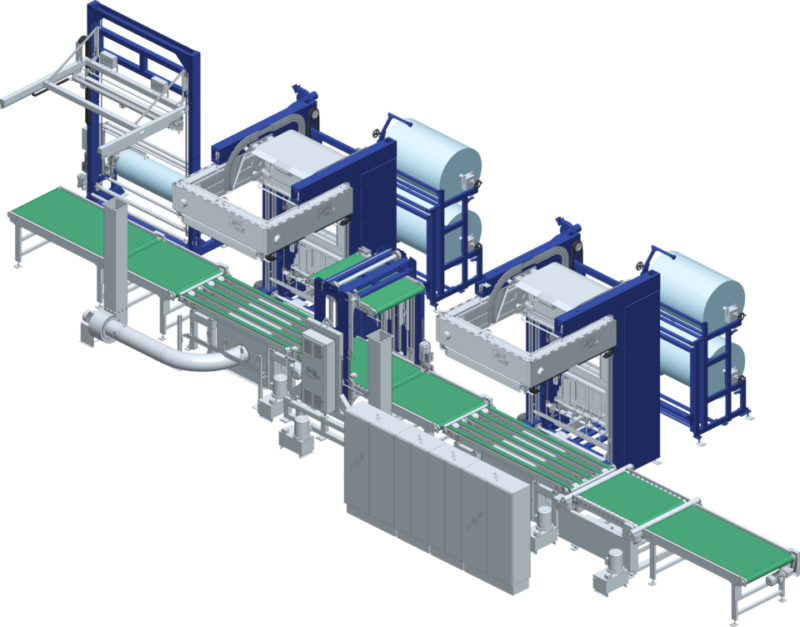

This technology is for example present in the palletless lines of OMS. These are modular and adaptable packaging plants, capable of producing stable packaging without the support of the wooden pallet without doubt one the major cost of the packing.

The constant partnership that unites OMS and SEW offers the possibility to develop end-of-line packaging solutions that are extremely effective and innovative thanks to the adoption of cutting-edge components. The SEW parts used have a key role both in the packaging phase and in the handling phase, guaranteeing high productivity cycles.

Regarding the first phase, the line uses DRL asynchronous servo geared motors controlled by MOVIDRIVE technology that allow to contain typologies and costs while guaranteeing performances similar to those of servo motors.

Instead, movement is carried out by means of motorized roller conveyors and involves the use of gear motor with decentralized MOVIMOT technology, which make it possible to drastically reduce the start-up and wiring times and the size reduction of the electrical panels.

The communication of the pallet line less OMS is managed using an Ethernet bus directly integrated on the components used; this allows a rapid data transmission, a simplified wiring and a the possibility to analyze the operating data remotely.

The reliability and the experience of SEW components, expressly requested for palletsless plants always operating in extreme conditions (high temperatures, highly dusty, humidity and relative condensation cause high temperature changes), have played a decisive role in the selection as supplier of OMS, thanks to ad hoc application packages, especially in the application field of packaging.

AVR900 + ADV system

AVR900 is an automatic rotating ring wrapping machine.

Is it suitable for all applications where high production rates are required especially in the beverage sector so it can be easily inserted into packaging lines.

The rotating ring designed without sliding electrical contacts guarantees: less maintenance, reduced electrical consumption, drastic reduction of overheating and risks of electric shock consequently a greater overall safety of the machine.

This model can be equipped with one or two pre-stretch reels of film and allows the wrapping cycle to be started and stopped at any palletized load height. Rotation takes place by means of a high-strength belt whose speed is adjustable directly from the operator panel.

At the end of cycle the film is not heat-sealed (thus avoiding emission of harmful fumes) but through a system patented by “OMS” where the queue of film is positioned under the previous wrap to ensure a perfect finish.

Another system developed and patented is the pre-stretching carriage: it guarantees a stretching ratio of film up to 300%, without the use of additional motor or electrical contacts.

This results in greater reliability of packaging, load stability, reduced film consumption and maintenance.

AVR900 can be equipped with top-sheet device which allows the wrap of pallet dust or water proof ensuring a complete packaging on five sides.

OMS has also developed a fundamental and useful accessory for all companies wishing to put their brand on the packaged product; this option is integrated into a special reel holder unit where roll of advertising band is positioned. Results a saving of time for the application and protection of its own brand within the same packaging.

The advertising band can be applied at any point of the packaging thanks to a special ring vertical reading system, programmable according to required height.

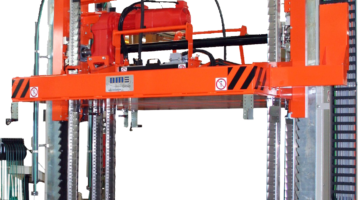

A very small space available to install three strapping machines

This model of strapping machine has been purchased by an important multinational corporation of the United States.

Their first necessity was to have an implant made of two lines that could manage a very high productive performance per hour.

For this Company it was also very important to stick to all the security restrictions they had in their plant and to manage in the best way possible the limited space of the site of installation of such a complex implant.

OMS supplied an impant made of:

Three strapping machines model 082 that had two mobile strapping heads TR14HD equipped with a special device that allows to insert corner perimetral protections.

This configuration grants the maximum flexibility and productive capacity in function of the type of the product that needs to be packed.

Perimetral systems, devices and muting photocells to manage the security of the whole implant.

Centering and rotation device, transport of the pallets designed in particular according to the space available.

6,30 meters, the higher OMS machine ever made

Our distributor Gordian Strapping has provided a stretch hooder for Sheffield based timber merchants and animal bedding suppliers McClure Timber Supplies t/a Greenwood Forest Products. Standing 6300mm from the floor, it is the tallest OMS manufactured stretch hooding machine in the UK.

McClure required a stretch hooder for baled sawdust and baled wood shavings for cattle, horses and other livestock to improve presentation and pack security in transit and also to enable pallets to be stored outside without risk of water ingress. With space at a premium, a high level of engineering knowledge and ingenuity were required to find a solution that met the clients’ need with a minimum of fuss and down-time.

Gordian Strapping installed an OMS manufactured IS43 stretch hooder off the conveyor centre line because of space restrictions and incorporated a specially designed shuttle conveyor to enable the packages to be positioned correctly for hooding.

The benefits were many:

greater pack security with the product now secured firmly to the pallet,

no sideways movement in transport,

the ability to hood packs in line straight after the baler,

Improved visible pack presentation and ultimately less returns and less damage as the pack remains in exactly the same condition it leaves McClure’s. McClure’s Owner and Managing Director, Richard McClure feels the solution has been a real boon to his company.

OMS stretch hooding IS46

The OMS stretch hooding IS46 is an authomatic machine which can be part of an authomatized production line, it performs the packaging of the goods through bags of extensible film.

These bags can be made of different materials and they have different compositions, their main function is to protect the goods during the transport and the storage and also granting that the packaging will be stable and waterproof.

Through the use of coils of extensible tubular film it is possible to hood packs of different shapes and mesures.

During the design of the machine the main movements of the hooding cycle have been divided in 3 different phases; this choice led to the achievement of high production performances (up to 250 packs/h), always granting high quality aesthetic of the packed product.

Thank to the innovative coil-holder system it is possible to manage up to three coils at the same time, the three coils are installed at the level of the ground to enable the operator to substitute them without any downtime.

This system is designed to enable the operator to have easy access to the main parts of the machine during the maintenance and this guarantees a great saving of time which is one of the many qualities of this model of hooder.

This machine is actually one of the most performing machines of its cathegory that you can currently find on the market.

MAIN ADVANTAGES:

Performance: high productivity (up yo 250 packs/h)

Timing: no downtimes and no wasting time to change the coil

Eco-friendly: energy saving, because the film doesn’t need to be heated

Stability: the packaging with the stretch film is safer and more resistant, it also grants an high stability during the transport

Protection: the hood protects the goods from water, dust and bad weather conditions

Environment: less pollution tank to the less use of film

41° ASEAN GLASS CONFERENCE

OMS Italy and OMS Singapore were one of the official sponsors at the 41° Asean Glass Conference held from the 9th to the 12th of October 2017 at Da Nang (Vietnam).

This occasion represented a moment in which different cultures met and it has been a great opportunity to share new ideas, toughts and solutions concerning the glass sector in particular. “Glass Digital Era”was indeed the subject of the event.

As reported in an article pubblished on the Glass World Wide magazine: “South East Asia has emerged as a major powerhouse for glass tableware production in recent decades. The development of a sizeable, local middle class and rising purchasing power have been pivotal, in addition to which, the region has become an important exporter to Europe, the Americas and the rest of Asia.”

OMS was glad to take part at this conference, first of all because of the opportunity to become aware of the new challenges in the glass sector and also to improve its technological skills concerning the glass market in the digital era.

AN OMS IN NORTHERN AFRICA

Tunisia, Morocco and Algeria are part of the so called Maghreb region situated in northern Africa. Usually considered difficult and uncharted lands they are however full of magical landscapes and great economic opportunities.

These Countries are now beginning to grow in the world market and to make use of the occidental technologies and opportunities.

The Oms Maghreb headquarter in Tunis has been inaugurated the 17th March 2014, this city with its charme represents a perfect point of connection to manage the ever- growing request of the african market.